Precise Colors for Reliable Workwear: DMIx and the Color Control Module – MatchBox

In workwear, everything revolves around consistency, especially when it comes to colors.

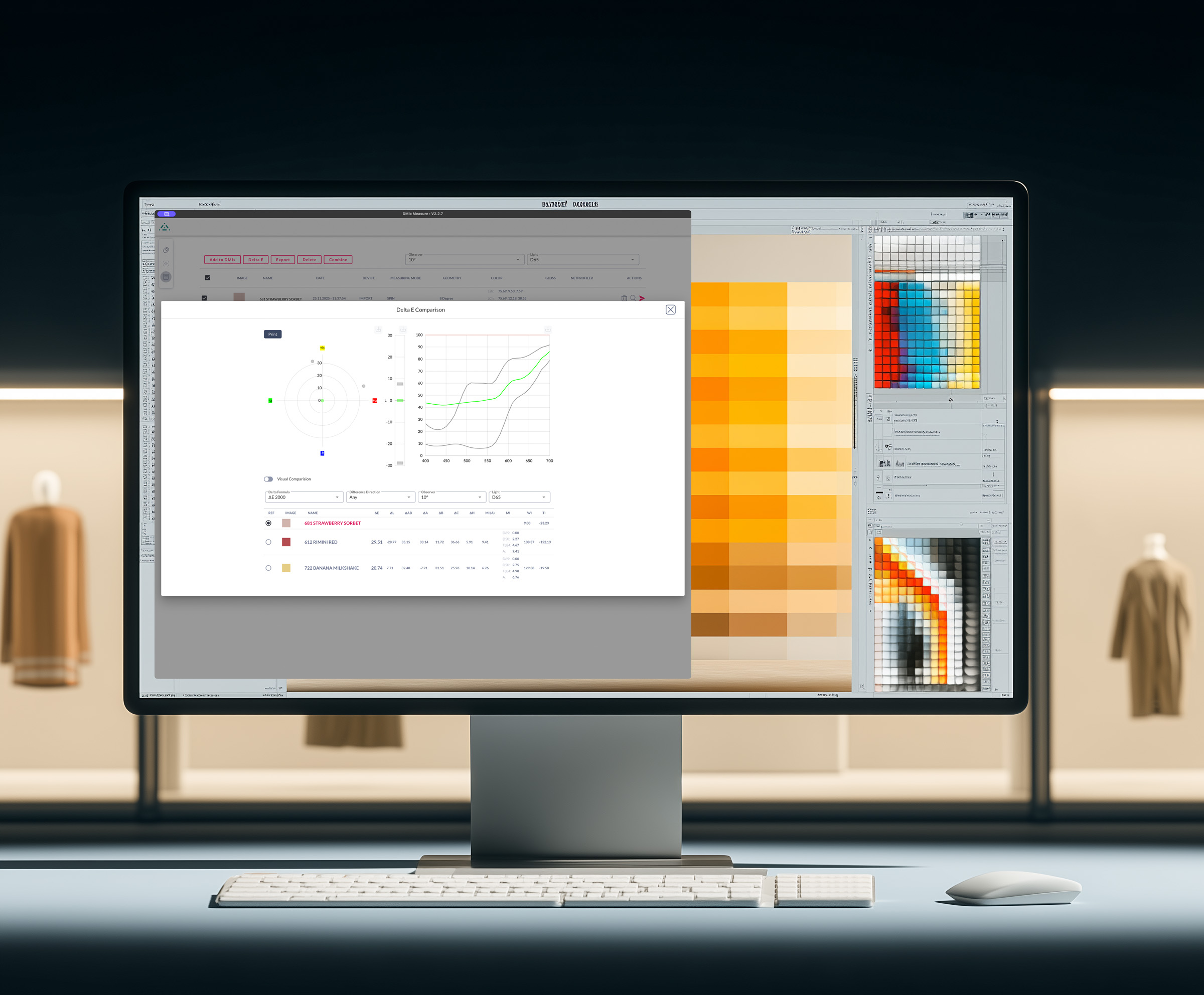

DMIx ensures that every nuance is correct, from the digital design all the way to the finished garment. With DMIx, we safeguard color consistency through our color control module.

How do we do this?

First, through precise color measurement and a digital color archive. Second, through clear standards and defined tolerances that are binding for everyone.

Third, through our color control module, which ensures that these standards are maintained throughout the entire production chain.

And the best part:

DMIx makes it easy for your suppliers to connect. We ensure that your suppliers are seamlessly integrated into the system and use the same color standards.

his creates a smooth process in which every stakeholder knows exactly which colors apply — and you receive consistent, reliable workwear.

Click here to reach out and learn how DMIx ensures

reproducible colors across your supply chain.

Why Spectral Color Measurement Is So Crucial for Workwear

Colors in workwear not only need to look good — they must be reliably reproducible.

This is where spectral color measurement comes into play. It is the technical core of DMIx and the reason why color consistency becomes measurable and controllable.

What does spectral color measurement mean?

Instead of storing only RGB or Lab values, a spectrophotometer measures how a material reflects light across the entire visible spectrum (approx. 400–700 nm).

Every material therefore has its own kind of “color fingerprint.”

- Why is this so important?

Colors look different under different lighting conditions

Standard color values are not enough when a jacket looks different in a warehouse, outdoors, or on the production floor.

With spectral data, the color remains clearly defined under any lighting. - Different materials behave differently

Cotton, polyester, blends — each material absorbs dye differently.

Spectral measurements detect these differences precisely and make them comparable. - Suppliers can reproduce colors accurately

With spectral data, suppliers understand not just which color is meant, but how it must be produced physically.

This drastically reduces errors and re-dyeing. - Objective data instead of subjective perception

No more debates about “too red,” “too green,” or “we see it differently.”

The data decides — not the monitor or ambient light.

How DMIx makes spectral data usable

- Digital color archive: Every color is stored as a spectral dataset.

- Standardized tolerances: DMIx automatically defines allowed deviations.

- Color control in production: With the DMIx Color Control Module, spectral data is used to check every dyeing process for compliance with standards.

- Easy supplier integration: Suppliers gain immediate access to the same precise color standards and work instructions, which integrate seamlessly into their processes.