What is the true impact of going digital?

Since beginning its digital transformation with DMIx®, IMPETUS Group shares improvements in efficiency and sustainability within its product development processes.

Leading Portuguese textile manufacturer, IMPETUS Group, is on a mission to reduce its environmental impact and increase efficiency, and one step of this journey includes moving to fully digital collection development.

In order to accelerate their digital transformation, IMPETUS Group partnered with ColorDigital GmbH to use its interactive digital platform, DMIx. Within the DMIx ecosystem, brands and their suppliers (from different levels of the supply chain) can collaborate in real-time across all areas of textile design, product development, and production, enabling fully digital product workflows using color technology, 3D technology and master data.

By taking advantage of existing connections IMPETUS Group had with various software applications, DMIx made it very easy for IMPETUS to develop its first product line in a fully digital workflow. For these digitally developed products, IMPETUS has collected comparative data on various efficiency and sustainability savings for producing a men’s organic cotton boxer short within the sampling and prototype processes:

• Reduced time by over 99%

• Reduced waste by 100%

• Reduced CO2 emissions by over 99%

• Reduced water usage by 100%

• Reduced resource depletion by 100%

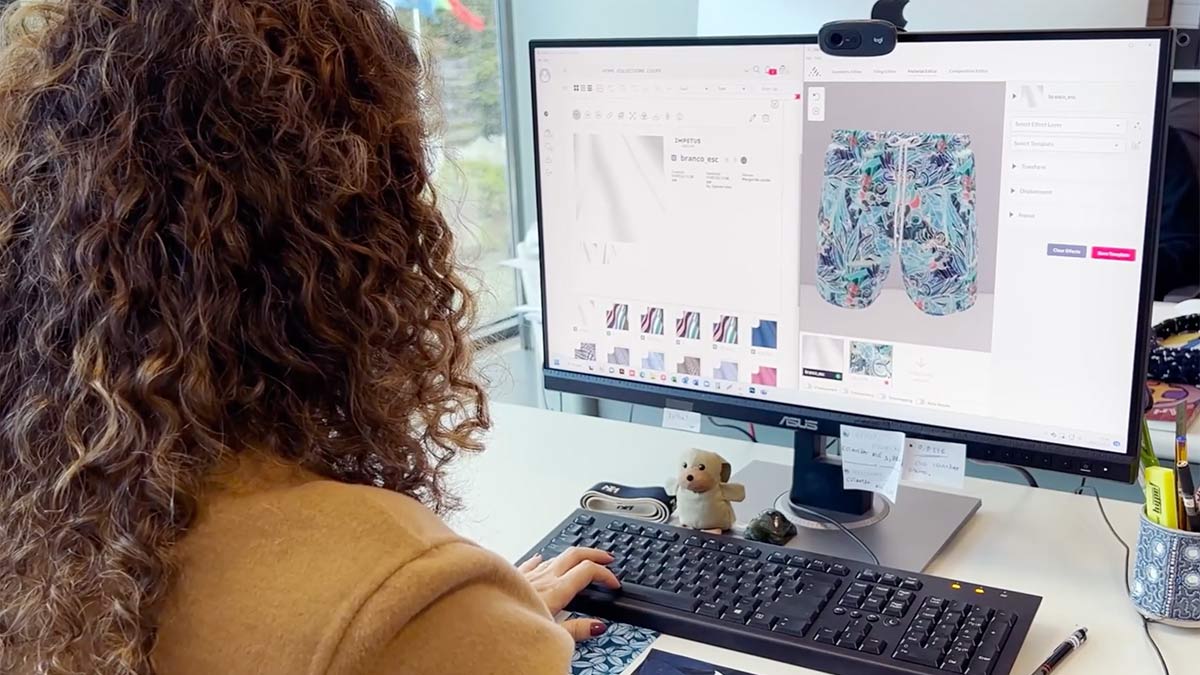

“The transformation to fully digital workflows enables us to make quick changes to colours, prints and fitting applied to a digital garment dressed on an avatar,” says Nuno Sousa, Graphic Designer at IMPETUS Group. “Previously, these checks and changes would require us to create new samples, involving time-intensive processes such as weaving, knitting, dyeing and sewing, just to test it out. With garments designed in CLO 3D that are transferred into the DMIx environment, we can apply any digital materials/colour and even visualize the final product using DMIx 3D-Magic. This outcome – a digital 3D prototype – is of such high quality that we can use it for internal approvals and present items and collections directly to customers.”

IMPETUS Group has now fully transformed its workflows with its own brands and is beginning the same journey with its private label customers.

“This data-supported study by IMPETUS is the perfect example of how DMIx enables brands to improve the efficiency of their workflows, whilst also reducing their environmental impact,” says Gerd Willschütz, COO and Co-Founder of ColorDigital. “We’re excited to continue our partnership with IMPETUS Group as they digitalize additional workflows, helping them to achieve their ambitious sustainability goals.”

Click here to view a video of the process implemented at IMPETUS Group or read more in the “IMPETUS takes it digital” case study.

By loading the video, you agree to YouTube’s privacy policy.

Learn more